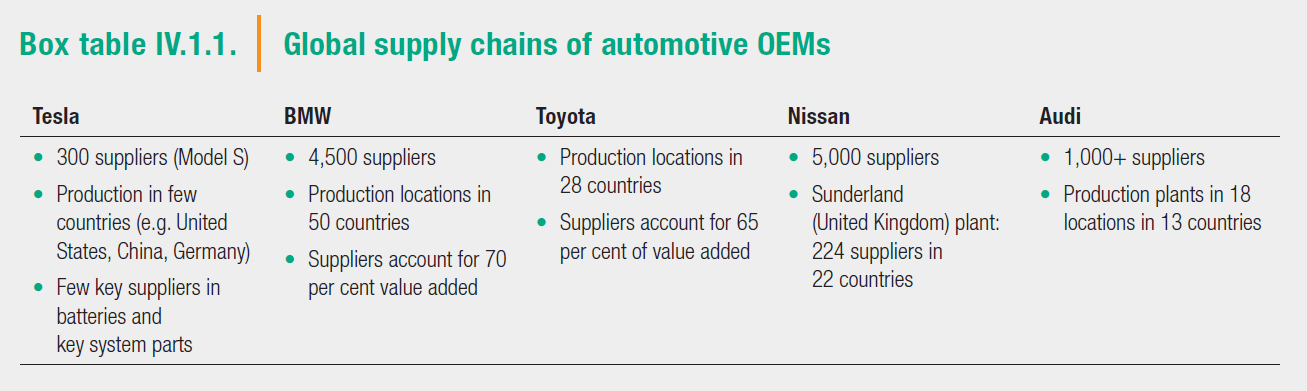

The automotive industry is projected to see major changes in the year leading to 2030 as the world moves away from internal combustion engine vehicles to electric vehicles (EVs) according to the World Investment Report 2020 published by UNCTAD. Today the auto industry is a highly complex industry with many Original Equipment Manufacturers (OEMs) and multiple layers of suppliers spread across many countries. Thousands of auto parts companies exist whose only purpose is to supply the parts – which include everything from car seats to batteries to park plus and everything in between – they make to the auto makers. In a way auto makers can be called as auto assemblers since they just buy a bunch of parts and assemble them together like putting together a puzzle or a Lego toy. With that said, below are a efew interesting facts:

- 15 countries in the world are major auto hubs today accounting for 88 percent of the global auto production in 2018.

- The drivetrain for an internal combustion engine has more than 2,000 parts while EVs have only 20.

- The value added are concentrated in just a few parts with the battery in EVs accounting for about 40 percent of the total cost of the vehicle. Hence EV supply chains tend to be fewer.

- For example, EV maker Tesla has only 300 suppliers spread across a few countries against thousands of suppliers for a traditional automaker.

- High concentration of value added around battery producers and software providers will also reduce geographic spread.

- While the global auto supply chain is spread over many countries today, the emergence of EVs would lead to newer infrastructure for EVs and other related economic activities.

Click to enlarge

Source: World Investment Report 2020 – International Production Beyond the Pandemic, UNCTAD

Related stocks:

Disclosure: No positions